Usage

Calculate supply planning with Easy Purchasing¶

You can calculate the supply planning with Easy Purchasing by the following steps

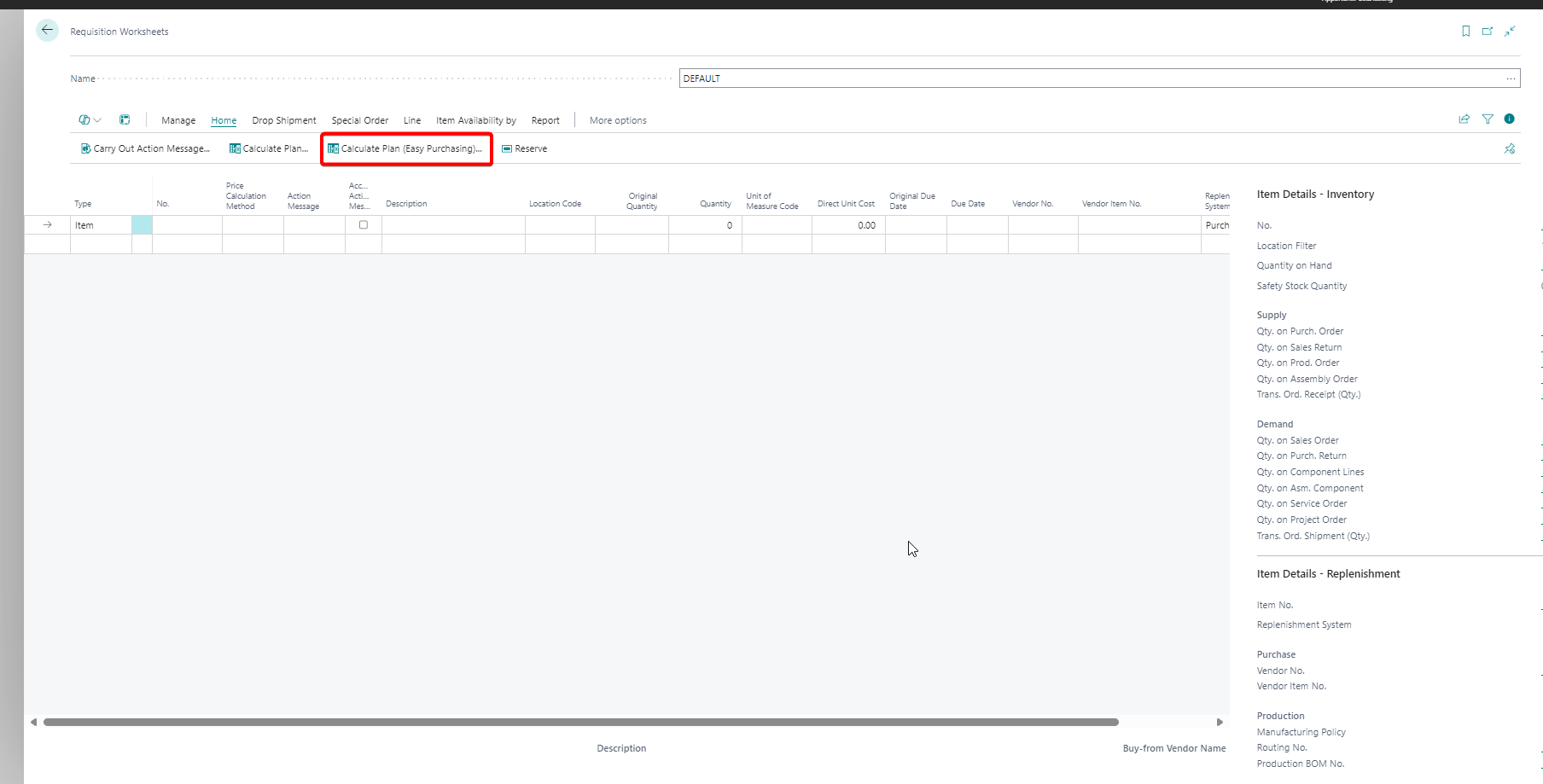

- Open the Requisition Worksheet

-

Click on the action Calculate Plan (Easy Purchasing) in the ribbon to start.

-

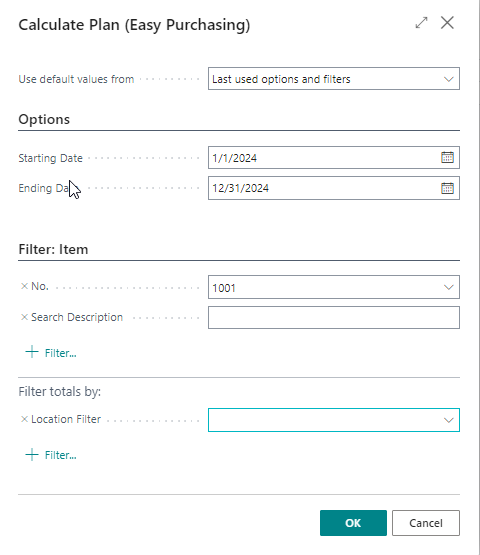

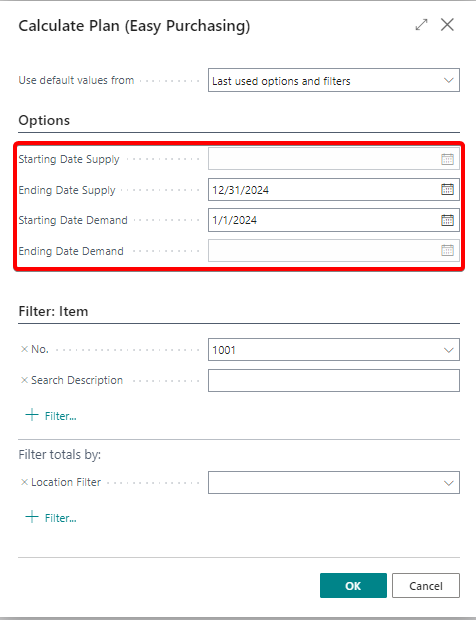

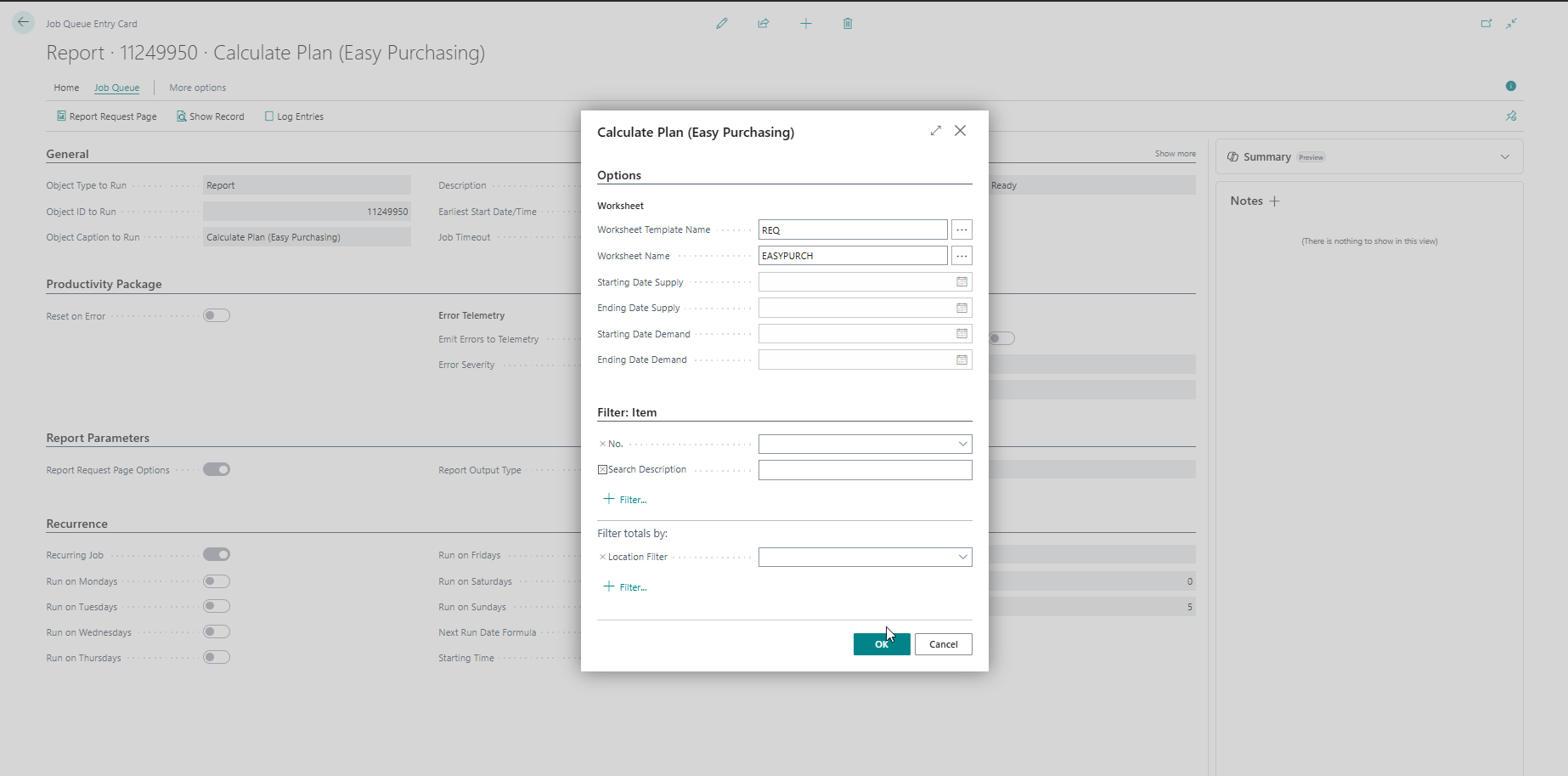

Enter the parameters in the request form and press OK to calculate the plan. This will fill the Requisition Worksheet and lets you process the output according to the default Business Central flow.

-

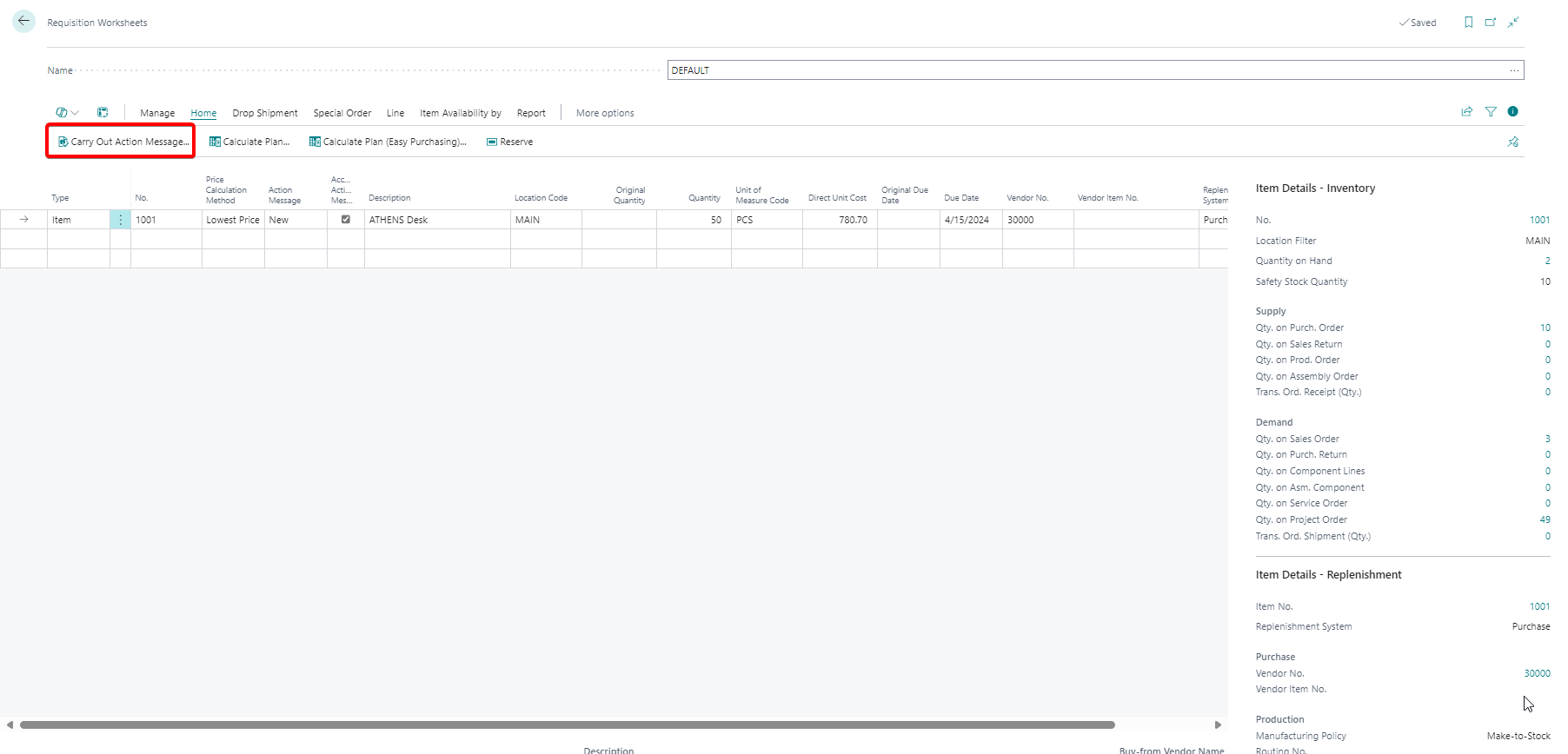

Press Carry Out Action Message to generate the Purchase Orders.

Understand the plan¶

Understand the starting point¶

- Only Items where the Replenishment System is set to Purchase will be included

- The Requisition Line will use the Vendor No. from the Vendor No. setup on the Replenishment FastTab of the Item

Understand the used quantities¶

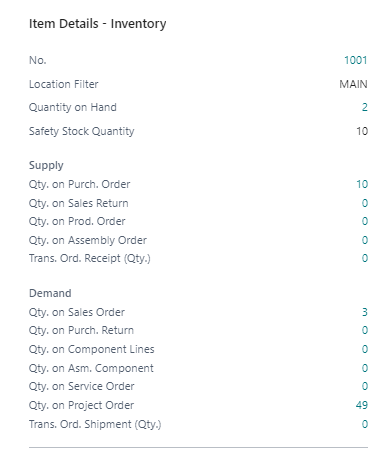

Easy Purchasing provides a new factbox to explain the quantities used in the calculate plan

For each requisition line you have the following information:

- Item: Item that the supply is needed for

- Location: Location where the supply is needed for

- Quantity on Hand: The inventory of the item currently available on the location

- Safety Stock Quantity: The safety stock of the item for the location

Note

When Calculate Safety Stock only for Main Location in the setup is enabled, the safety stock quantity will be displayed as zero for all other locations

Supply¶

All the outstanding supply for the item and location.

It takes into account the quantities in:

- Purch Order Lines

- Sales Return Order lines

- Productions Order Lines

- Assembly Order Headers

- Transfer Order Lines (to receive)

Demand¶

All the outstanding demand for the item and the location. It takes into account the quantities in:

- Sales Order Lines

- Purchase Order Lines

- Production Component Lines

- Assembly Order Lines

- Service Order Lines

- Project Plannings Lines

- Transfer Order Lines (to receive)

Understand the calculation of the quantity¶

Easy Purchasing will calculate the quantity to supply according to the following formula:

Supply calculation

Quantity to supply = Safety Stock Quantity + Total of Demand - Total of Supply – Quantity on Hand

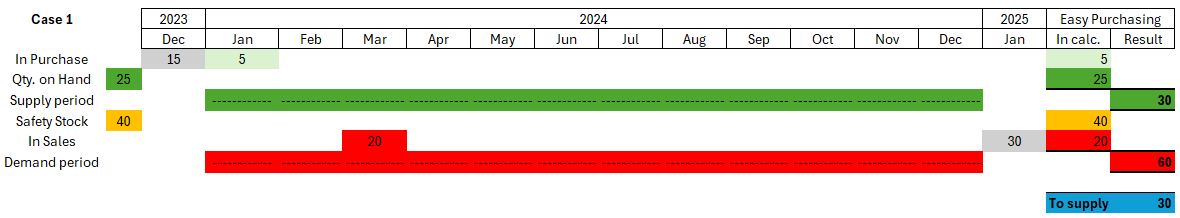

Case 1¶

| Item Details | Qty. | Case 1 | Date parameter | Date |

|---|---|---|---|---|

| Qt. on Hand | 25 | Starting Date | 24/01/01 | |

| Safety Stock | 40 | Ending Date | 24/12/31 | |

| In Purchase | 15 on 23/12/01 | Different Starting & Ending Date | No | |

| 5 on 24/01/10 | Starting Date Supply | n.a. | ||

| In Sales | 20 on 20/03/2024 | Ending Date Supply | n.a. | |

| 30 on 10/01/2025 | Starting Date Demand | n.a. | ||

| Ending Date Demand | n.a. |

Case 1

Quantity to supply (30) = Safety Stock Quantity (40) + Total of Demand (20) - Total of Supply (25) – Quantity on Hand (25)

Understand the use of starting and ending dates in the calculation¶

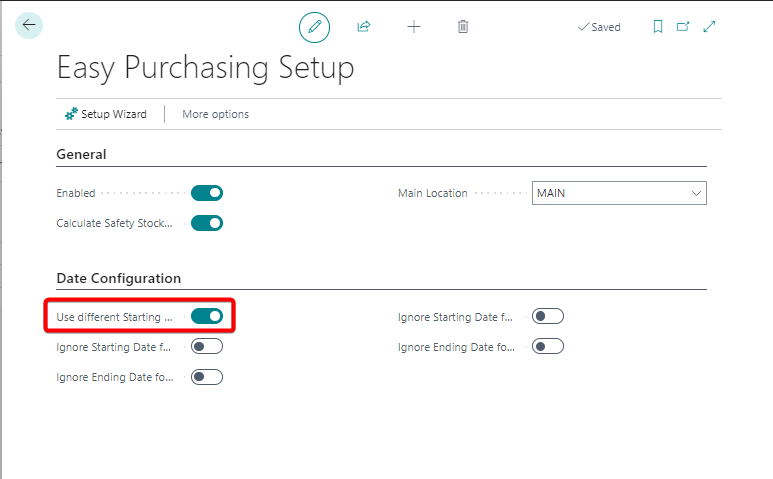

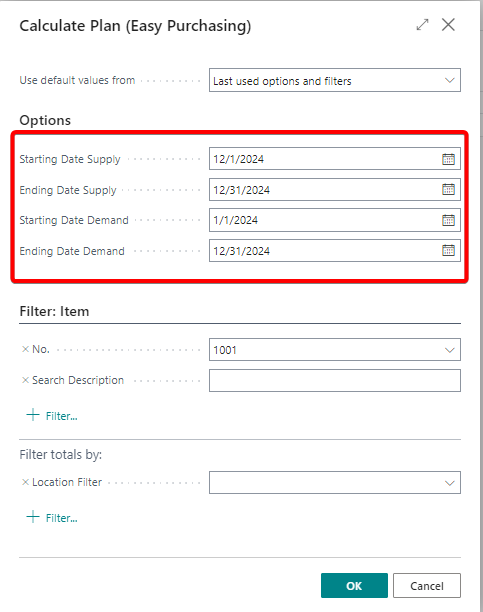

Easy Purchasing requires there is a Starting Date and an Ending Date for the calculation. All requisition and supply will be filtered according to the given Starting Date and Ending Date in the request form. If you want to use alternate periods for the calculation of supply and demand you can enable Use different Starting Date and Ending date for Supply and Demand calculation in the Easy Purchasing Setup

Case 2¶

| Item Details | Qty. | Case 2 | Date parameter | Date |

|---|---|---|---|---|

| Qt. on Hand | 25 | Starting Date | n.a. | |

| Safety Stock | 40 | Ending Date | n.a. | |

| In Purchase | 15 on 23/12/01 | Different Starting & Ending Date | Yes | |

| 5 on 24/01/10 | Starting Date Supply | 23/12/01 | ||

| In Sales | 20 on 20/03/2024 | Ending Date Supply | 24/12/31 | |

| 30 on 10/01/2025 | Starting Date Demand | 24/01/01 | ||

| Ending Date Demand | 24/01/01 |

Case 2

Quantity to supply (15) = Safety Stock Quantity (40) + Total of Demand (20) - Total of Supply (20) – Quantity on Hand (25)

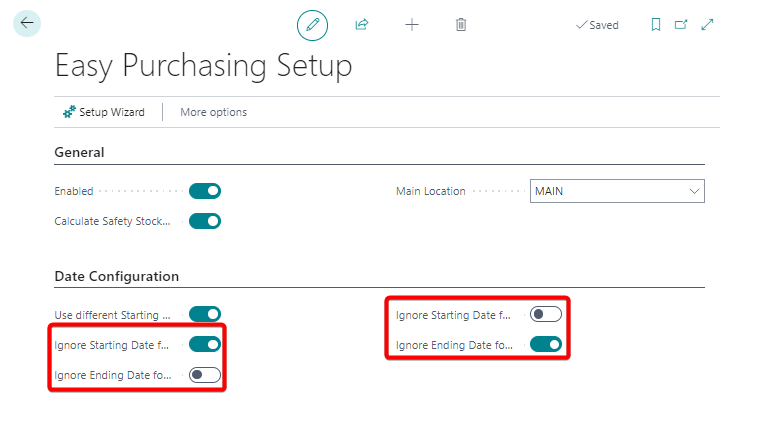

You can set up the Starting and Ending Dates to ignore a Starting or Ending Date. This can be useful when you want to include all previous supply for example. When you set the option to ignore a Starting or Ending Date in the Easy Purchasing Setup, the date filter for the field will be set to unlimited when calculating the supply or demand. The ignored field will also be disabled in the request form Calculate Plan (Easy Purchasing)

Set Ignore Starting Date for Supply Calculation to TRUE

Effect on Calculate Plan: Sets Ending Date Supply to 31-12-2024 and will calculate all the supply till date 31-12-2024.

set Ignore Ending Date for Demand Calculation to TRUE

Effect on Calculate Plan: Sets Starting Date Demand to 1-1-2024 and will calculate all the demand from 1-1-2024.

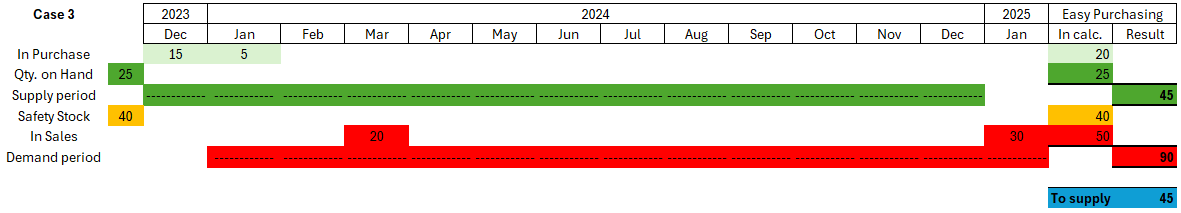

Case 3¶

| Item Details | Qty. | Case 3 | Date parameter | Date |

|---|---|---|---|---|

| Qt. on Hand | 25 | Starting Date | n.a. | |

| Safety Stock | 40 | Ending Date | n.a. | |

| In Purchase | 15 on 23/12/01 | Different Starting & Ending Date | Yes | |

| 5 on 24/01/10 | Starting Date Supply | Ignored | ||

| In Sales | 20 on 20/03/2024 | Ending Date Supply | 24/12/31 | |

| 30 on 10/01/2025 | Starting Date Demand | 24/01/01 | ||

| Ending Date Demand | Ignored |

Case 3

Quantity to supply (45) = Safety Stock Quantity (40) + Total of Demand (50) - Total of Supply (20) – Quantity on Hand (25)

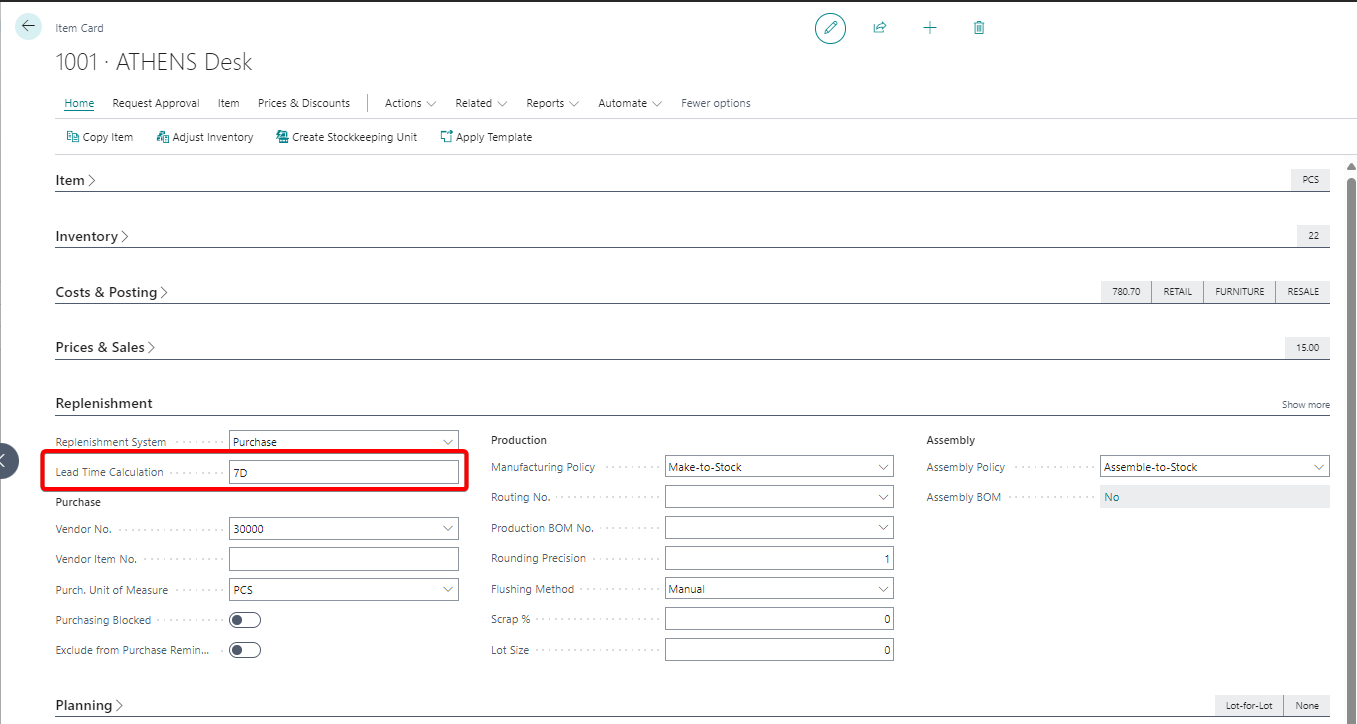

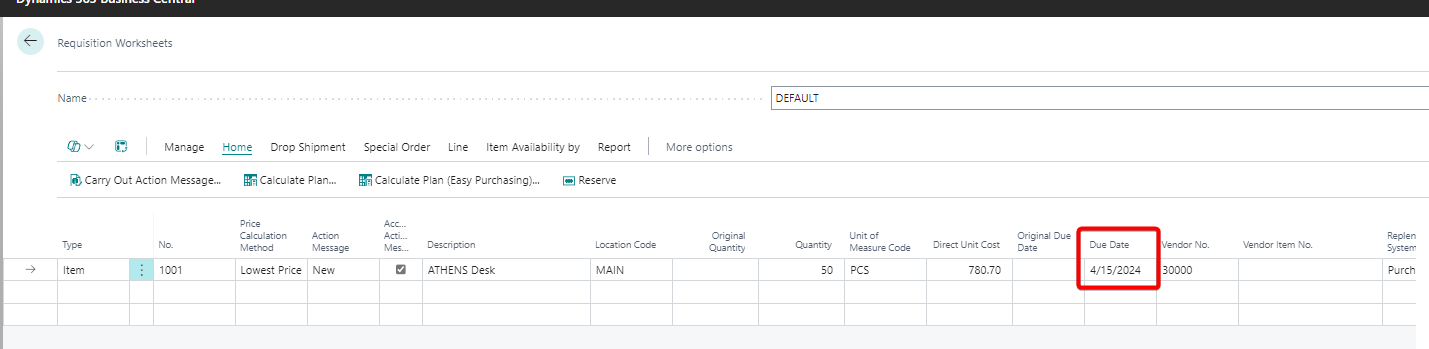

Understand the calculation of the date¶

The calculated Due Date is the Workdate + the Lead Time Calculation of the Item in the Requisition Line.

Example

Due Date (2024/04/15) = Workdate (2024/04/08) + Lead Time Calculation (7D)

Understand the limitations and it's use¶

Easy Purchasing will only generate one requisition line per item per location. This means it won’t take a lot parameters into account, but will provide an understandable output.

The following parameters are NOT taken into account:

- SKU’s

- Variants

- Unit of Measures other than the Base Unit of Measure

- All parameters on the Replenishment FastTab & Planning FastTab of the item except: Vendor No., Lead Time Calculation & Safety Stock

- Replenishment System Assembly & Production

- Supply by Transfer

- Forecasts

- Action Messages Change Qty., Reschedule, Reschedule & Change Qty. and Cancel

Schedule Calculate Plan¶

You can schedule the execution of the Calculate Plan (Easy Purchasing) in a Job Queue. Hereby you can run the Calculate Plan (Easy Purchasing) outside work hours and check & carry out the results later on.

You can use the Schedule button while running the report or create a new Job Queue entry for Report 11249950.

Use the following link for more information about Job Queues: Use job queues to schedule tasks